About Us

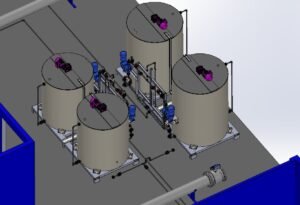

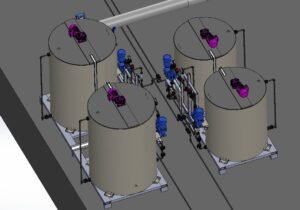

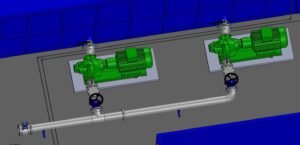

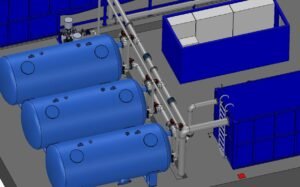

Photo Gallery

♦ Introduction

IBNYAN TOWERS International Contracting andGeneral

Trading Company / Ltd. was established in 1999 AD in the

city of Mosul in Iraq. For more than 20 years, the company

worked in the field of mechanical works, and dealt in

particular with the Directorate of Water and Sewage

of Nineveh. The company developed and expanded until

the year 2004, when it was officially registered and approved,

to be an important and vitaltributary for national industries.

In the year 2006, the company started manufacturingdrinkingwaterfiltration

complexes, and to increase the volume of business required

by the company, and because of the security conditions

in the city of Mosul, a work site was opened in the Syrian

Arab Republic (the industrial area in Aleppo governorate),

and it was equipped with the latest machines and

machines to develop production and improve its quality and

perfection in a timely manner. Standard, in

addition to that, a new section was introduced,

which is the section for drawing and rolling

sheets up to 50 mm thick.

In 2014, a new branch of the company was opened in Erbil Governorate, northern Iraq (Kurdistan Region), in order to keep pace with the development in the region and to increase the demand for mechanical work in it. Sophisticated workshops equipped with the latest machinery, equipment and manufacturing machines were opened.

♦ Our company has implemented many activities as: Supplying, Installation, Design ,Rehabilitation and Manufacturing.

In 2021, a new factory was established in the

city of Mosul, with a surface area of 10,000

square meters. It contains all the equipment

needed to manufacture the iron parts

A- A vertical welding machine with a height of

9 m. (submerged welding machine).

B- A rolling machine for bending iron to a

thickness of 30 mm

C- Welding machines powered by CO2 & Ar.

D- Other various machines and equipment.

In addition, IBNYAN TOWERS International

Contracting and General Trading Company /

Ltd. It operates in other fields, as it has a plant

for the production of oxygen and nitrogen gas

with a production capacity of 600 cylinders /day.

♦ What We Do?

For more than 20 years, our company provide high quality services by our qualified engineering staff and workers.

♦ Our Services

Disgn

-

Manufacturing

Supply

Installation

Rehabilitation

♦ Water traetement

River Water Treatment System (WCU) Greenhouse/irrigation WTS Sand and Activated Carbon Filters Water Softeners Rain Water Treatment System Disinfection System Water Bottling Machines Antiscalant and other agents

♦ WASTE WATER TREATMENT

Physical Treatment:

Grit Removal

Screen

Oil and Grease removal

Scrapers

DAF (Dissolved air

flocculation unit)

Biological Treatment:

Extended aeration active sludge systems

Containerized Treatment

SBR (Sequence batch reactor)

MBBR (Moving bed biological reactor)

MBR (Membrane Bio reactor)

Anaerobic Treatment Systems

Chemical Treatment:

Coagulation

Flocculation

Neutralization

Chemical Decanter

Sludge De-watering:

Activated Carbon filters

Filter press

Rail Press

Biofiltration

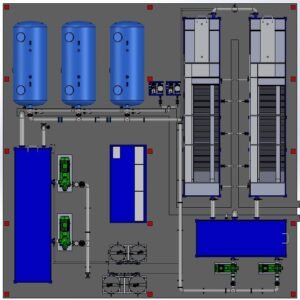

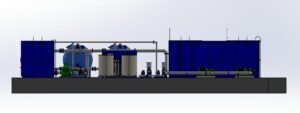

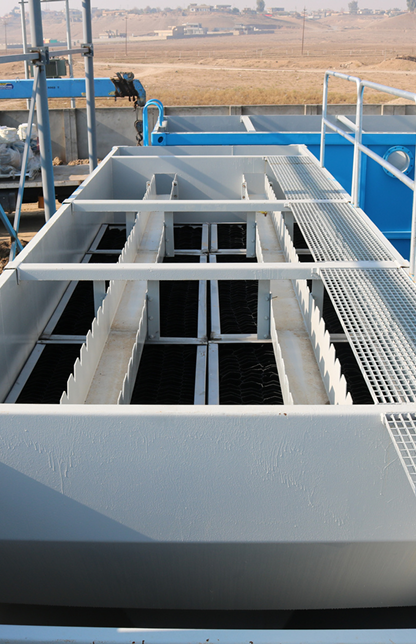

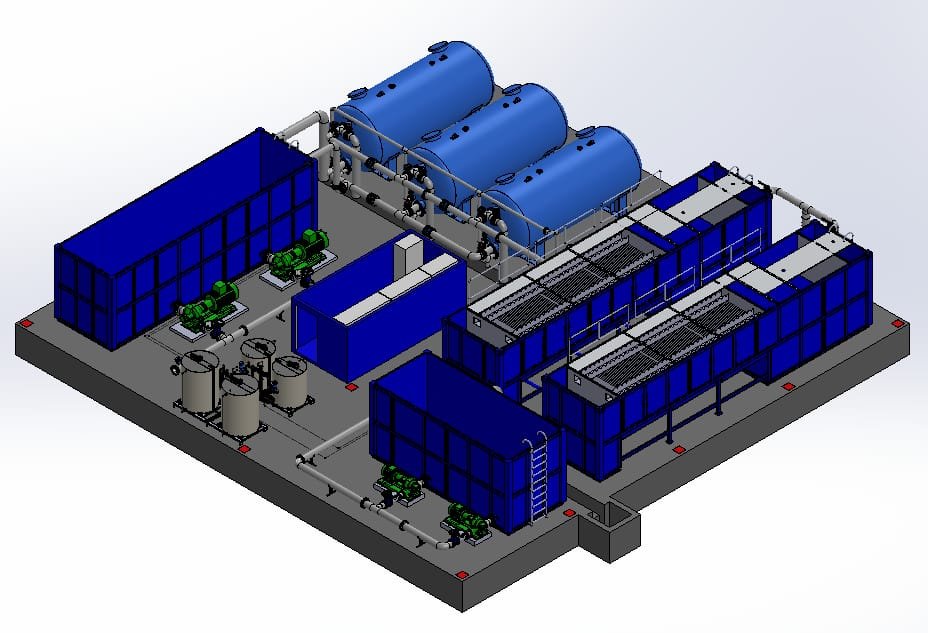

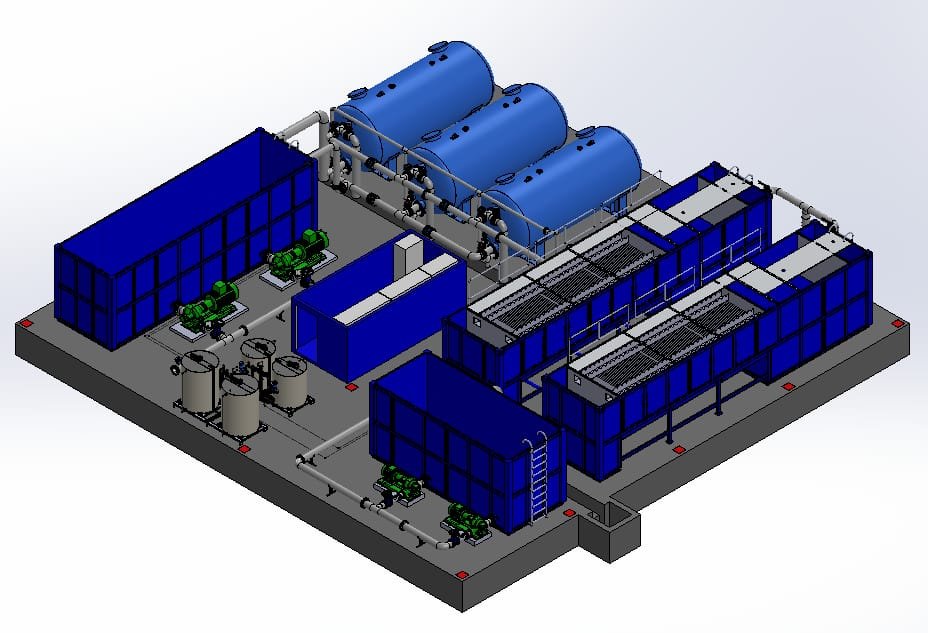

♦ RIVER WATER TREATMENT SYSTEMS

River Water Treatment Systems are the systems to treat river and surface water to usage water. To supply potable water from these units, there are generally followed by a reverse osmosis system. These units mainly preferred in middle east countries where the amount of surface water is large and lots of short cuts happen. in order to carry the system from one spot to another these systems can be designed as containerized also. Because the systems are easy to transport, economic, and user friendly, they are preferred to supply good quality water. As Al Ibnayan Towers, we can manufacture these units in various capacities to supply water from a compound to whole city. With the valves using the system can be run either in automatic or manual modes. The piping of the system can be PVC/stemless/Galvanized lamellas can be inserted and fitted at maintenance time for easy access. There are also walking paths on the container in order to control the processes.

STANDARD TECHNICAL SPECIFICATION:

Epoxy Coated ST37 carbon steel body

Lamella from GRP/PVC

Alum Dosing System

Rapid and Slow mixers

Stairs and walking path

Treated water tank

Control Panel

Chlorination System (Liquid/Gas)

Electro Magnetic Flowmeter

Automatic Sand Filter

PLACE OF APPLICATION:

Factories, hotel, ports, any

residential area whic is

close to a surface water

source

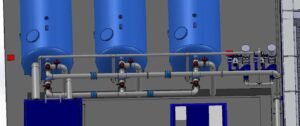

♦ FILTRATION SYSTEMS

SAND FILTER:

It is the filtration method used to

remove the suspended solids in water. Sand

filtration is used to treat particles, causing

turbidity. In the filter tank, there is quartz

sand with different sizes and anthracite.

Sand filters are essential part of water

treatment processes, in domestic and

industrial water treatment systems.

sand filter increase the treatment

efficiency of the following treatment

unit. Also in waste water treatment

systems, sand filters are used to

supply sufficient water quality for

irrigation.

ACTIVATED CARBON FILTER:

Activated

carbon mineral is widely used in both water

and waste water treatment systems to remove

smell and odor molecules. also used to treat TOX

(Total organic halogens), AOX (Absorbable organic

halogens), Chloroform, and chlorine compounds. Activated

carbon filters also increase the efficiency of the following treatment system. in

waste water treatment systems, activated carbon is used to decrease the values

of BOD (biological oxygen demand), COD (Chemical oxygen demand) and TOX.

STANDARD TECHNICAL SPECIFICATION:

Anti-corrosive filter body (FRP, epoxy

coated ST 37, Stainless steel)

Programmable automation valve

Flow and timer control

Automatic backwash

3-6 bar working pressure

Max. 10 bar test pressure

Max. 40C water temperature

220v/50 Hz power supply

PLACE OF APPLICATION:

Pre-treatment for reverse

osmosis/ultrafiltration units

River, sear or well treatment

Irrigation and greenhouse

Hotels, camping,

swimming pools

♦ WATER SOFTENERS

Water softeners removes calcium and

magnesium ions which is called as temporary

hardness from water, to protect all your

water system, machines from calcified up

and to supply better taste. Water softeners

work with ion exchange technique.

Sodium ions (Na) in the body of the

softening resin, change places with the

Calcium (Ca) and Magnesium (Mg) ions

the water. At the state of no more sodium

ions on the resin surface to exchange with

calcium and magnesium backwash must

take place. Backwash is done with salty

water in softeners. Water softeners can be

design single and duplex according to the

costumers need and backwash is set due to

flow control or time control.

TANDEM WATER SOFTNERS:

Tandem softeners are perfect

solution to remove the hardness in industrial places which use water

continuously 24 hours. all valves used in tandem softeners do service, backwash, and

rinsing applications automatically.

STANDARD TECHNICAL SPECIFICATION:

Anti-corrosive FRP or epoxy coated ST 37

carbon steel body

Programmable automatic valve

Electrical actuators valve for larger capacities

Flow or time control

Automatic backwash

3-6 bar working pressure

Max. 10 bar test pressure

Max. 40C working temperature

Food grade softener resin

Electrical Con. 220V/50Hz

PLACE OF APPLICATION:

Water Boilers and cooling

towers

Supply water softening

Industrial process waters

usage and potable water

Irrigation

♦ DOMESTIC WASTE WATER TREATMENT

As Al Ibnayan Towers in domestic waste water treatment systems are working domestic waste water treatment systems we are working different methods, based on biological treatment technologies developments, waste water characteristics, product quality limitations, customer choice, climatic and environmental conditions may effects the chosen process. Al Ibnayan Towers applies suspended and/or attached growth processes for aerobic systems. its also possible to apply aerobic treatment technologies depending on raw wastewater quality and/or quantity.

♦ INDUSTRIAL WASTE WATER TREATMENT

As Al Ibnayan Towers is carrying out waste water treatment solution for textile,

leather, paper, dairy products, food processing, petroleum refineries, metal

finishing industry, etc . Wastewater sourcing from industrial applications differ

quantitively. Raw wastewater characterizations defined by examining the

production process in details. Treatability tests are carried out at our laboratory

and then BAT (best availably technology) for wastewater treatment plant is

suggested under optimum conditions. its also possible to recycle the treated

water of WWTP for some specific industries Tertiary and/or advanced treatment

systems shall be enough for recycling at most cases. Material selection for

industrial wastewater treatment plants can be either concrete, carbon steel

and/or FRP.

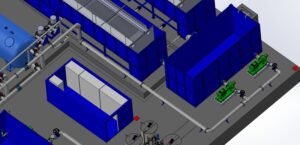

♦ PACKAGE WASTE WATER TREATMENT

Package treatment is the general name for compact and modular treatment system with maximum sizes of 240cm width, 300cm height, and 1500cm length. these systems are portable and the capacity may be increased with additional packages.

Package waste water treatment Systems can

bemanufactured from:

Steel construction (St 37 Carbon steel, AISI 304

Stainless steel, AISI 316 L/Ti stainless steel).

Plastic construction (HDPE, PP)

GRP

STANDARD TECHNICAL SPECIFICATION:

Epoxy coated carbon steel bodyBasket screenBlower & diffuserWeir

Sludge recycle pumpChlorine dosing systemPLC Control Panel

♦ MBR-MEMBRANE BIOREACTORS SYSTEMS

In treatment of waste water membrane bioreactors, takes place of activated

sludge process and final sedimentation tank. The combination of biological

degradation and membrane filtration provides high efficiency in the removal of

COD (Chemical oxygen demand), BOD (Biological oxygen demand), and

ammonium nitrate. MBR systems can be summarized as the activated sludge

process and UF (Ultra filtration) system coming together. They generally consists

of sedimentation/aerobic tank membrane bioreactor tank and they are

combined system formed from one bioreactor and one filtration unit. MBR

systems are smaller in sized when compared to conventional activated sludge

processes, with less sludge formation and better product water quality. With the

developing technology, energy consumption in MBR systems is decreased so

that the number of MBR system starts to increase. By the help of the diffusers

placed at the bottom of the MBR cassette, the mixture of air and liquid is

established and also by the turbulence effect of the diffusers the membrane

surface can be cleaned.

MBR Systems:

Innovated activated sludge technology

Liquid-solid separation take place

Pathogen bacteria and viruses protection

Product water quality is high

Require less space

STANDARD TECHNICAL SPECIFICATION:

MBR modulesMicro Filtration

Product and backwash pump

Chemical cleaning systemBlowerDiffusers

Electrical actuator valvesMonometer

Product water flowmeterpH meter

Pressure transmitter for pressure dif.

Control panel with PLC

PLACE OF APPLICATION:

Treatment of Grey water

Hotels and Camping

Industrial Sites

♦ Our Projects

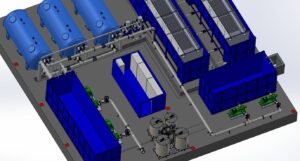

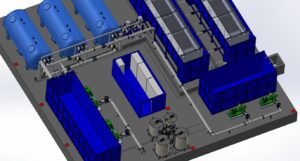

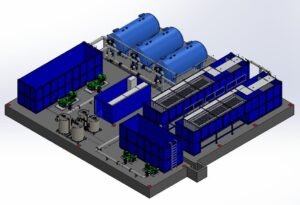

- 1. Design and manufacture of a water filtration plant with a capacity of 60 m3 / h to the oil

fieldinNahrawan, with very high specifications and advanced control systems

for the purpose of controlling remote operation, as the intake plant is 27 km away

from the main filtration plant. Year 2023

- 2. Manufacturing of water filtration plants with a capacity of 400 m3/h and 5 stations for

Maysan Governorate. Year 2023

3.Design,manufacture, supply and installation of drinking water filtration plants

with a production capacity of (200 & 500) m3 / h for the contract (W1 & W2) with (27) units affiliated to the Ministry of Municipalities, Housing and Public Works funded externally by the KFW security loan organization, and the

beneficiary is the Nineveh Water Directorate in villages south of Mosul. The advisory body

supervising the work is Khatib & Alami Engineering Design Company, during a record

period of 22 months. Where our company is characterized as being the only certified

manufacturer of aggregate units for the KFW organization. In the year 2021-2022.

- 4. Equipping a filtration plant with a capacity of 500 m3/h to Al-Faris State

Company for the year 2021.

- 5. Equipping a filtration station with a capacity of 200 m3 / h to the village of

Al Safina, affiliated to the Salah Al-Din Directorate, and funded by the UNDP.

year 2022

♦ Our Projects

- 6. Supplying and manufacturing the iron bridge tributaries of Al-Alam Bridge / Salah

Al-Din Governorate, affiliated to Al-Faw General Engineering Company, with 30

tributaries, where the dimensions of the tributaries start from a height of (4.90 m and

a length of 12 m) to (2 m and a length of 14 m) and in various other measurements. for the

year 2020.

- 7. Supplying cables of Turkish origin to Al-Faw

General Engineering Company with different

diameters affiliated to the Baiji refinery. for the

year 2019.

- 8. Supplying and installing a combined water unit with a capacity of 200 m3 / h in the

Jamjaman area Governorate in 2018. in Sulaymaniyah

- 9. Design, manufacture and installation of pressure filters for artesian wells to purify

drinking water in Erbil Governorate, in 6 neighborhoods within the governorate, where

the filters are cleaned automatically. Year 2017.

- 10. Design and implementation of a filtered

water project in Baiji with a production

capacity of 1200 m3 / h. It works with the latest

electrical control systems through PLC

systems, and it is controlled remotely by

engineers, with the extension of intake pipes

with a diameter of 600 mm and a length of

6000 meters in 2013-2014.

- 11. Establishing a sewage treatment unit for

Qayyarah Hospital (200-bed capacity) in

Nineveh Governorate in 2014.

- 12. Ductile Iron Pipe And Fitting K9 for the

Kirkuk water project, the second phase,

with a capacity of 12000 m3 / h, from

the German company Duker, forstations:

(High Lift, Low Lift Pump, Chlorine System

and Alamo System)

With a value of (570,000 €) in 2013-2014.

- 13. Supplying Ductile Iron Pipe And Fitting

K9 for the Kirkuk water project, the

second phase, with a capacity of 12000

m3 / h, from the Italian company

Sertubi, for stations:

(Flash Mixer, Puddle Pipe (For all Project)

and Yard Pipe type: Bolted Gland)

With a value of (2,350,000 $) in the year

2011-2012.

♦ Our Projects

- 14. Supplying Ductile Iron Pipe And Fitting K9 for the Kirkuk water project, the second phase, with a capacity of 12000 m3 / h, from the

Italian company Fondedil, for stations: (Backwash Filter and FILTER HOUSE SPECIAL

PIPES and Fitting) With a value of (4,600,000 $) 2013.

- 15. Supplying locks for the Kirkuk water project, the second phase, with a capacity of 12000 m3 / h, from the Italian company TIS, for a filter system of 60 filters, at a value of (1,219,000 €) in 2013.

- 16. Supplying locks for the Kirkuk water project, the second phase, with a capacity of 12000 m3 / h, from the German company VAG, for stations: (High Lift, Low Lift Pump, Flash Mixer (Type: Penstock), Transmission Line and Yard Pipe)

With a value of (1,790,000 €) in the year 2013 2014.

- 17. Design, preparation and implementation of

the Al-Sahrun water project in Mosul, with a

production capacity of 1500 m3 / h. The

beneficiary: Nineveh Water Directorate in the

years 2010-2012.

- 18. Supplying ductile iron pipes of different

diameters for the Kirkuk water project – the

second phase, with a production capacity of

12,000 m3 / h. Al-Bably is the agent of the

Saudi Amiantit Company and the Italian

company Sertubi, which are specialized in the

manufacture of ductile pipes.

- 19. Supplying all gantry cranes for the Kirkuk

water project – the second phase, with a

number of 14 cranes, tonnages of (1, 2, 3, 5, 10)

tons, in 2013.

- 20. Expansion of the left coast project

with a capacity of 3000 m3/h from a

capacity of 12,000 m3/h to a production

capacity of 15,000 m3/h, including the

design, supply and installation of the

necessary equipment for the project,

including (pressure filters with their

network of pipes that operate

automatically in addition to horizontal

pumps and the rest of the equipment

Completely), with the manufacture and

laying of a pipe with a diameter of 1200

mm and a length of 1100 meters inside

the project, with the connection of the

main pipe with a diameter of 1400 mm

of ductile type. 2008.

♦ Our Projects

- 21. Supplying and implementing a combined water unit with a production capacity of 500

m3 / h, which operates with a PLC control system to filter drinking water from the river, in

Salah al-Din Governorate.

- 22. Supplying water complexes for the purification of drinking water with different

capacities (250 / 200 / 100 / 75 / 50) m3 / h. There are approximately 37 French-designed

complexes.

- 23. Design and implementation of the flower water project with a capacity of (800 m3 / h)

in the city of Mosul in 2007.

- 24. Designing, equipping and implementing a complete system for the removal and

scraping of plankton (lichens) for the outlet of the low-draft station for the Unified Left Coast project with a capacity of 12,000 m3 / h inside the river basin at a depth of 4 m below the river level.

- 25. Installing the Hammam Al-Alil water project with a capacity of 250 m3 / h.

- 26. Installing a Bashiqa project with a capacity of 300 m3 / h.

- 27. Bishara manufacturing a water pump with a capacity of 1400 m3/h, and a lift of 90 m in the Right Coast Project, 4 pieces, with a budget for it in 2005.

- 28. Completely rehabilitating the old left coast

project.

- 29. Extending drinking water networks of

different diameters.

- 30. The company carried out various works, including (installing complete sets of pumps with different capacities

from (110 x 2400) m3/h to (50 x 100) m3/h)

- 31. Manufacturing a complete vacuum system with the assembly tank for the low-draft station in the Unified Al Yamini project with a capacity of 10,000 m3/h in 2007

- 32. Oil projects, including the supply and installation of refueling stations.

- 33. Manufacturing and installing grain milling plants with a capacity of (100 and 200) tons.

- 34. Manufacturing and installing ice plants.

- 35. Installing a heavy water treatment project in the city of Mosul / Al-Khadra neighborhood, with a capacity of (50,000) people, from the Nineveh Sewers Directorate.

- 36. In addition to other mechanical works.

- 37. Supplying and installing submersibles and horizontal pumps of

various sizes, supplying and installing locks of various sizes, and repairing mechanical filter gates.

♦ About Us

Finally, IBNYAN TOWERS International Contracting and General Trading Company / Ltd. is proud that it has, over the past years, studied, designed, manufactured and implemented many mechanical works, and used in the accomplishment of its tasks a large cadre of highly experienced consultants, engineers, technicians and workers.

albabilycom@gmail.com

www.alibnayantowers.com

00964 770 161 3559

Professional Engineers and Workers for a high quality projects!

Mohammed Marwan